CZ interchangeable purlin production

C&Z purlin interchange: manual type, within 10 minutes.

Purlin size change: by press buttons, driven by motor.

Delivery capacity: 180-220 sets each year, 20-30 sets standard machine in stock.

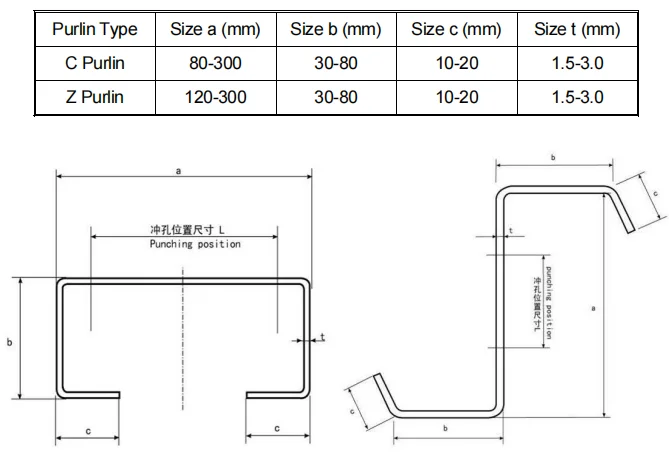

C&Z purlin specifications:

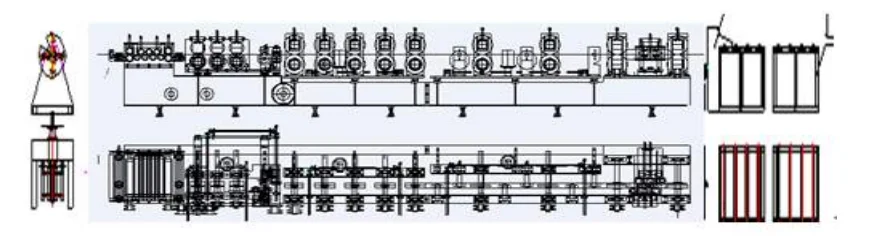

Work flow chart of the CZ interchangeable roll forming machine:

Uncoiling---(Pre-cutting system)---Leveling & guiding---Main roll forming machine---Hydraulic punching---Hydraulic universal cutting---Runout table

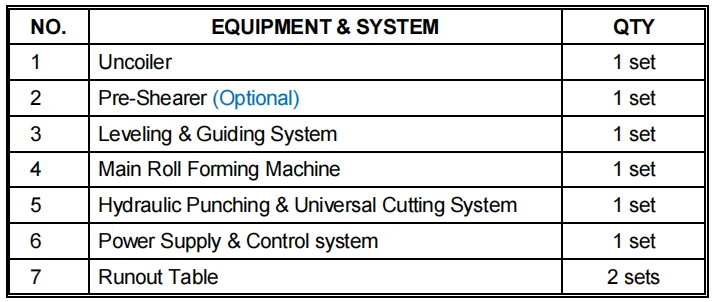

Machine components:

Detailed specifications:

1. General

The machine is able to produce both C and Z purlins for various sizes, easy operation and high effciency.

Speed: Max 25 m/min, (not including cutting and punching)

Main machine size: about 9600*1500*2000 mm.

Weight about 13T

Voltage: 380V-3P-50HZ or as your request

2. Raw material

Material type: hot rolled coil, galvanized coil

Yield strengh: 235 Mpa, 345 Mpa, 550 Mpa (Optional)

Thickness:1.5-3 mm

3. Decoiler

We can provide you two kinds of decoiler options to choose.

Option A: Manual decoiler

Posstive uncoiling

Loading capacity: about 6 T

Inner diameter: 380-580 mm

Option B: Hydraulic decoiler

Max weight: 6T

Inner diameter: Φ380-580 mm

Max hydraulic pressure: 12MPA

Hydraulic station motor power: 5.5 KW

With or without coil loading car

4. Per-cutting system

It's used for cutting the coil strip before forming.

The pre cutter is individual controlled by buttons which is installed on cutting frame.

5. Leveling & guiding system

Leveling system: Top 3 and bottom 4 rollers, with extra 2 coulpe of pinch rollers.

Leveling roller diameter: Φ80/100 mm

Rollers are solid shaft with heating treatment, polishing and galvanizing.

Guiding system including guiding shaft and guiding rollers. Their width is adjustable in order to suit for verious steel strips

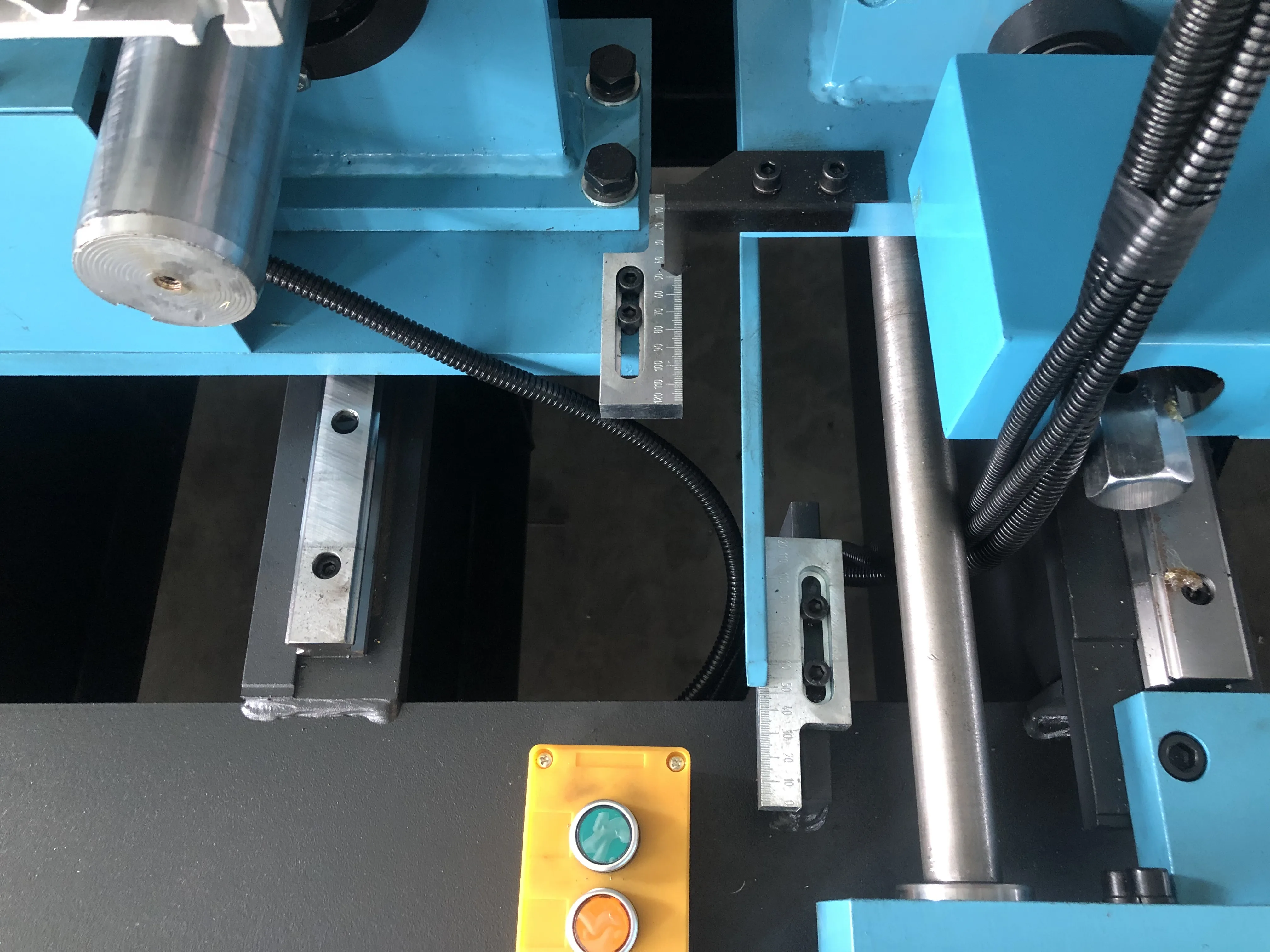

6. Main roll forming machine

Roller station: 18 roller stations, chains transmission.

Roller material: GCr 15 with heat treatment, polishing and galvanizing.

Main motor: hydraulic driving, power: 22 KW with air cooling system.

Main shaft: 40Cr with heat treatment, polishing and galvanizing.

Machine frame: welded by iron plate, with flat planer finishing machining. The levelness is measured by electronic level meter.

Machine surface adopts powder coating before assembly.

CZ interchange: turn over the roller box to 180 degree.

Size change: by press button. Motor drive, electrical control, continuosly adjustable.

Including 10 set special roller straightening unit and another 4 sets rollers straightening unit to ensure purlin will not cause curve, bow sweep and twist.

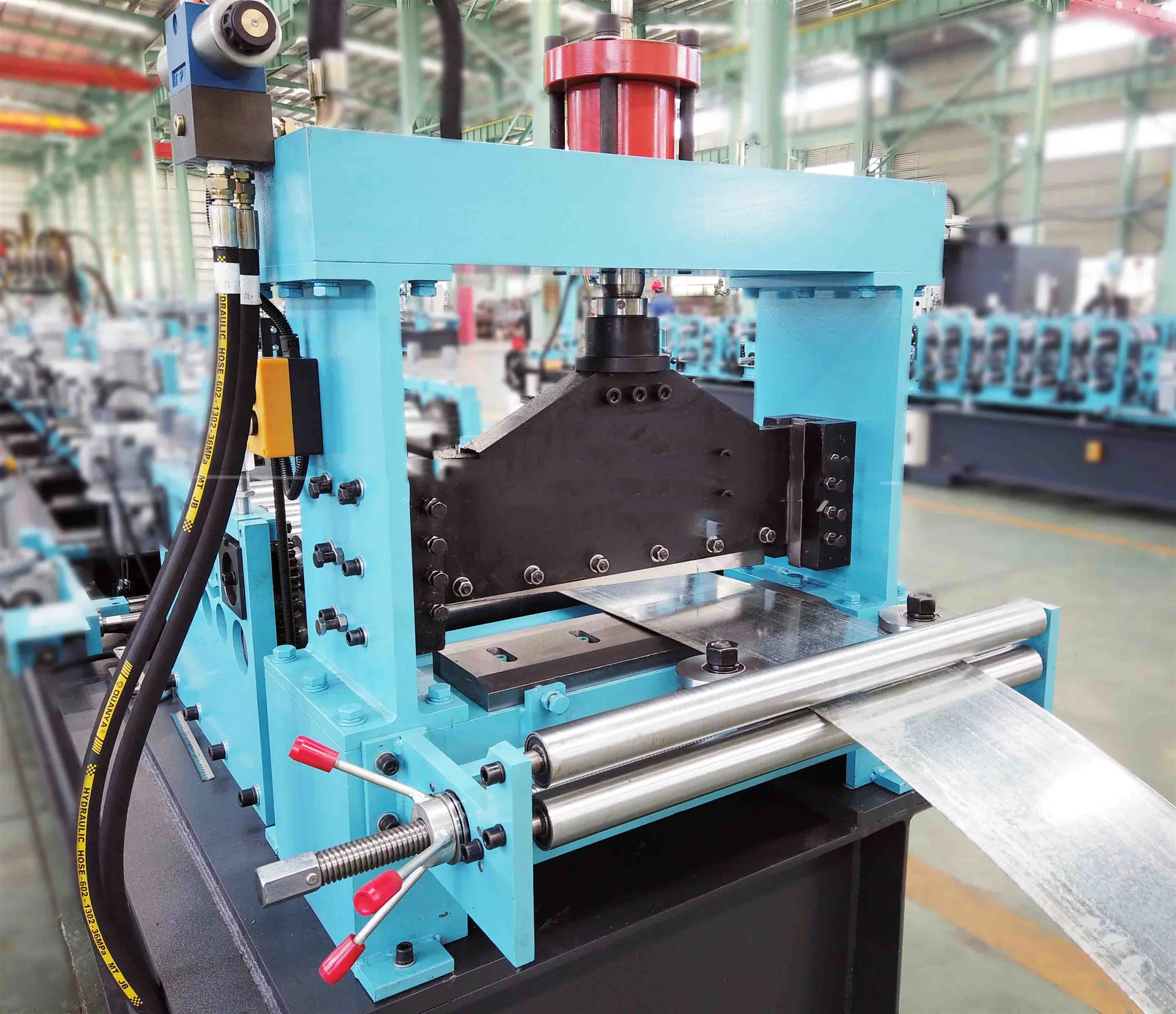

7. Hydraulic punching & cutting system:

Adopt post-punching and post-cutting, which can avoid the end-flared caused by front-cutter, and also can save roller service life.

Punching unit: 3 sets, one for web central punching and the other two for left/right web punching. Flange punching also available as optional system.

Punching die: 4 sets.

Cutter material: Gcr 12 MOV quenching.

Cutting length, quantity and punching are controlled by PLC system.

Punching and cutting when machine stop.

8. Power supply and control system:

Operation platform:HMI& buttons with English on it.

Control system: PLC(Ormon brand)

Key components adopts international famous brand

9. Output table

Two sets, 3 m length for each set, free roller type.

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations