Metal cutting& slitting machine

ZHONGTUO cutting& slitting machine can cutting metal colour galvanized steel coil, carbon steel, hot rolled,cold rolled.

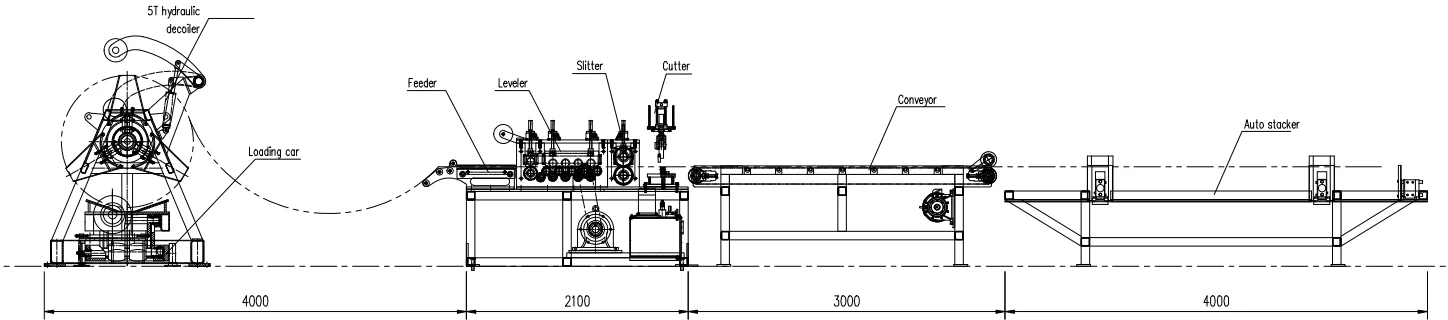

The whole production line include one set hydraulic decoiler with loading car, cutting& slitting machine, conveyor, stacker.

Total machine speed can reach 35 m/min, PLC control system control the running speed, cutting length, cutting quantity.

Decoiler and cutting& slitting machine use hydraulic working type, conveyor use electric type, stacker use pneumatic working type.

More technical parameters about machine, pls check below.

Work flow:

loading coil---uncoiling---leveling device---cutting sheet---convey table---automatic stacker

After you place order, we will give you a exact layout drawing according to your factory space for your convenience put the machine.

Main technical parameters:

| Series | Techincal | Parameter |

| Product | raw material | Colour coated galvanized steel/ galvanized steel / carbon steel/ hot rolled/ cold rolled |

| width | 1500 mm or can be customized according to your request | |

| thickness | 0.15-1.5 mm | |

| Decoiler with loading car | loading capacity | 10 Tons |

| feature | The decoiler is composition by pressure arm, corbel, that can help make the coil turning more stable. | |

| work type | Hydraulic type | |

| hydraulic motor power | 5.5 kw | |

| transmission motor power | 5.5 kw | |

| Leveling device and cutting device | shaft diameter | 50 mm |

| roller material | Inside 45# steel outside rubber | |

| drive motor power | 5.5 kw | |

| processing speed | 0-35 m/min | |

| roller station |

Up: 7 stations Down: 8 stations |

|

| cutter material | Cr12 | |

| Convey table | usage |

After shearing, the conveyor conveys the steel strip to the forming system |

| power | 1.5 kw | |

| Fully automatic stacker | length | 4 m |

| width | 1 m | |

| motor power | 4 kw | |

| PLC control system | language | English/Chinese or as your request |

| length tolerance |

+-1.5 mm/ 3 m |

|

| PLC brand |

Delta brand |

|

| Frequency brand | Delta brand | |

| Encoder brand | Omron brand | |

| Low-voltage apparatus brand | Schneider brand |

Here are each parts of the machine for your reference:

This is hydraulic decoiler with loading car, it can tensioning to hold tight the coil automatically.

And can make the coil uncoiling automatically. Have electric system to control these steps.

The loading capacity choose according to your coil weight, usually have 5T, 7T, 8T, 10T, 15T.

This is cutting& slitting machine, the step is firest leveling the material into flat condition, leveling roller quantity will depend on thickness.

Then material go through the slitting device, be slitted into many parts. After that, come to the cutting device.

It can shearing max 1.5 mm thickness material, the slitter quantity will follow your request.

We also can provide the cutting machine with other thickness, just let me know your requirement.

To get a accurate price, you need to provide material, thickness, width, slitting trips quantity. Then we will calculate the machine price according to these informations.

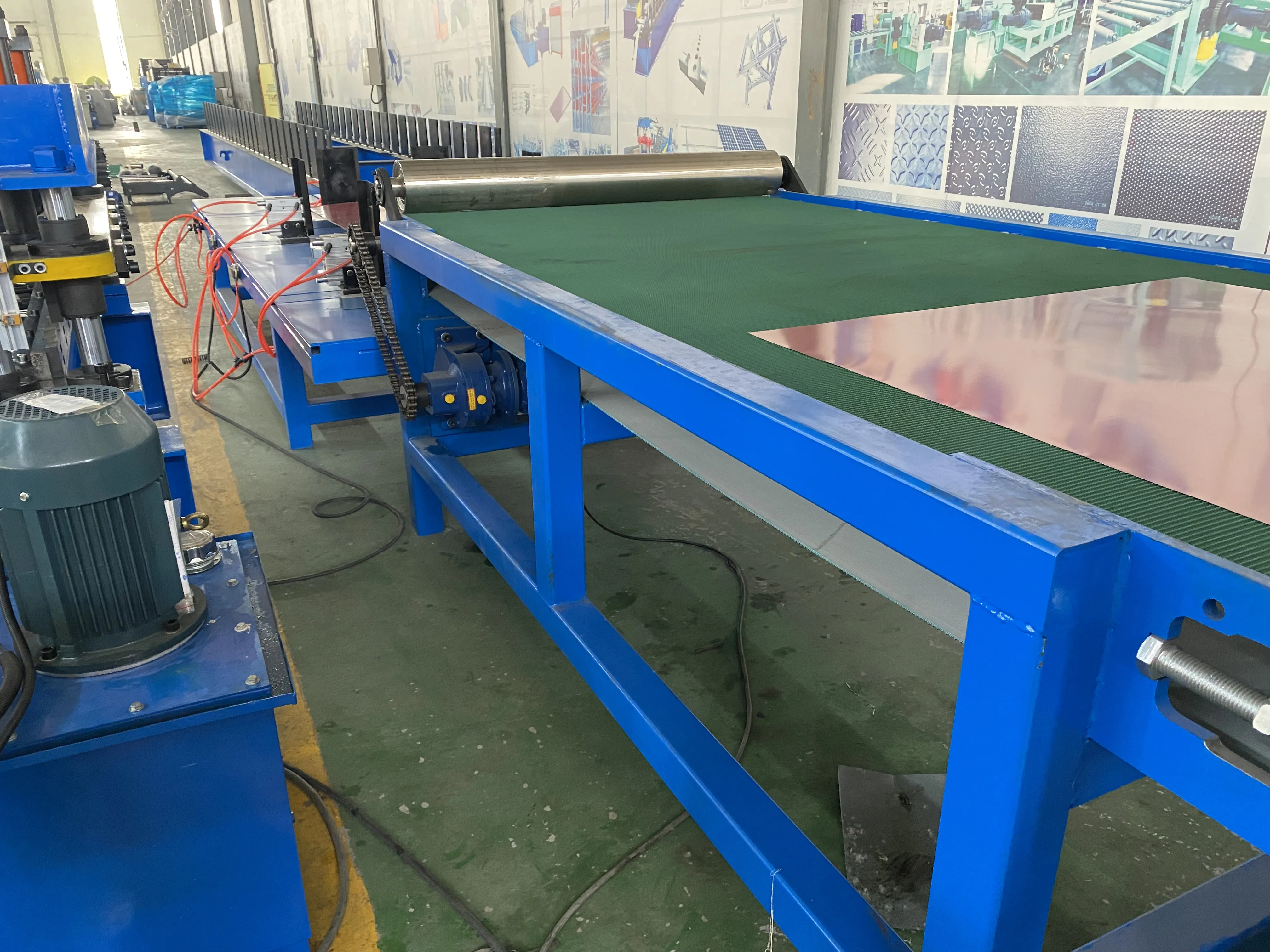

To ensure the production line speed, here we matched one set conveyor, the length can be customized according to your request.

It can fastly drive the material into stacker.

The stacker can make all metal sheet in row pattern with pneumatic working type.

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations