Steel decking rolling forming machin

It adopts latest designs. Its shearings structure is the most advanced among China supplier.

The design of inner structure of pillar is our patent.

Besides, all parts of this Steel structure floor deck forming machine are top quality to ensure perfect working.

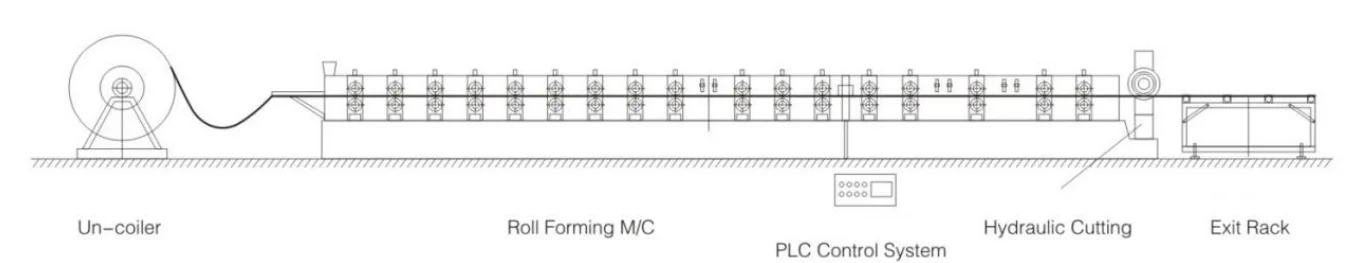

The working process of steel decking rolling forming machine:

Uncoiling---feeding material---main roll former---hydraulic cutting---run out table

The steel decking rollng forming machine packing list:

| Name | Quantity | Remark |

| Decoiler | 1 set | Manual |

| Main roll former | 1 set | |

| Hydraulic cutting | 1 set | |

| Hydraulic oil pump | 1 set | |

| Run out table | 1 set | 3 m length |

The main technical parameters of steel decking rolling forming machine

| Item | Name | Description |

| 1 | Decoiler | Loading capacity: 8 Tons |

| 2 | Machine roller stations | 28 roller stations or analysis according to your profile drawing |

| 3 | Main motor power | 30 KW |

| 4 | Transmission | By double chains |

| 5 | Roller material | Bearing steel with quenched treatment, chromed treatment on the surface |

| 6 | Roller shaft material | 45# steel with tempering treatment, 95 mm diameter |

| 7 | Cutting type | Hydraulic cutting |

| 8 | Cutting material | Cr 12 with quenched treatment |

| 9 | Hydraulic power | 7.5 KW |

| 10 | Control system | PLC control system |

| 11 | Electric element brand | Delta, Siemens,Schneider |

| 12 | Voltage | 380V-3P-50HZ (Or as your request) |

The speical design for the embossing device on steel decking rolling forming machine:

The first rolling station is especially form the embossing patterns, so we called the embossing stations.

Due to the material thickness, the first embossing rolling station will work in a large strength to rolling the patterns, we adopt four bearings inside to hold the shaft.

To prevent the shaft deformed.

The feature of floor decking tile making machine

We take the look from back of the machine, the chains transmission is covered by the yellow box. There are three carrying rollers on feeding system,

It can help the material feed into forming system much easily.

There are some gears in the left side of machine, the advantage of the gear is obviously:

There are 6 gears outside the structure which is on the shafts in the first three stations. The gears connect the upper shaft and down one,

the gear can drive the shaft moving actively. Normally, the chains only connect the shaft in the down layer, the upper shafts are moving passively.

But now we adopt the gear in the first three stations, both the down layer shaft and upper layer shaft are moving actively,

it can ensure the metal sheet feed into forming system in the same speed and same level.

Hydraulic cutting system

We adopt the three cutters on cutting system, this kind of cutting can prevent the product sheet deformed after cutting, and it's with a very low sounds.

The disadvantage is that will have 2 cm material waste for each cutting.

The hydrualic oil pump station is equipped with the cooling system. The cooling system can ensure the machine working

for hours continuously even working in a high temperature.

The PLC control system of floor deck roll forming machine

The whole set floor deck roll forming machine is controled by the PLC control station, the brand of PLC can be Delta, Siemens, Mitsubishi or other brand.

The language of control panel can be English, Spanish, Arabic and others, we can make it according to customers requests,

what we will do is that to make the operation easy for your workers.

The main feature of floor deck

1.Adapting to the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short time,

and can be used to lay the profiled steel plate on multiple floors, and the flow water construction of the layered concrete slab

2. In the use stage, the floor deck is used as the tensile reinforcement of the concrete slab, which also improves the rigidity of the slab

and saves the amount of steel and concrete. The floor deck is generally V-shaped, U-shaped, trapezoidal, and the convex part of the concrete is much less.

Unlike the soil board, it is a flat plate. The floor deck can generally save one-third of the concrete. Now the concrete is expensive.

3. The embossing on the surface of the profiled board creates the greatest bonding force between the floor deck and the concrete,

so that the two form a whole, with stiffening rib, make the floor deck system has high bearing capacity.

4. Under cantilever conditions, the floor slab is only used as a permanent formwork.

The length of the cantilever can be determined according to the section characteristics of the floor panel.

In order to prevent the cracking of the cantilever plate, it is necessary to match the negative reinforcement at the support according

to the design of the structural engineer.

5. The floor deck has a certain fireproof function. The floor deck material is galvanized steel. It is not easy to start water, and it is not easy to burn.

It can also block the spread of fire in a short time. To a certain extent, slow down the fire.

6. The floor deck also has some special functions, such as earthquake resistance. The floor deck is connected to the steel beam.

The floor deck has certain toughness. For example, in the event of an earthquake, the floor deck cannot be broken like concrete.

It is still a Overall, great chances to ensure the safety of people and property

7. Environmental protection,For short-term buildings, steel can be reused 100% if it is later removed.

8. The floor deck is laid very fast. If it is a high-rise building, it can be laid together on multiple floors. When it is poured concrete together,

it saves a lot of time, manpower and financial resources, and the fixing of the floor slab is also very fast,

it will take a short time with the special nailing machine. It was much simpler than a traditional wooden board.

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations