metal sheet slitting machine

Metal Sheet Slitting Machine

Description of Metal Sheet Slitting Machine:

The metal slitting machine’s function is to take large rolls of material (steel, aluminum, copper, etc.) and slit it into widths and lengths end users require for their machines (tube, strapping – almost an endless number of applications). The purpose of this paper is to describe Rockwell Automation’s standard approach to drives and controls for these machines.Metal Sheet Slitting Machine is used for cutting plate-metal into strips for nail-rod and it can uncoil metal sheet strip coil, then slit(cut) the metal sheet strip longitudinal, then rewind the slitted metal sheet strips, for getting narrow metal sheet strip coils. Metal Sheet Slitting Machine is for metal sheet strip coil cutting service center, press machine stamping punching, metal sheet strip processing,etc.

Advantages of Metal Sheet Slitting Machine:

Metal sheet slitting machine is designed for slit narrow strip from wide coil and then recoil it for further use. Meanwhile if you need to cut the length during slitting, we also can make for you. The thickness of material could be from 1 mm to 6 mm and the coil width could be from 900 mm to 1500 mm. The speed could be range from 25 m/min to 100 m/min.

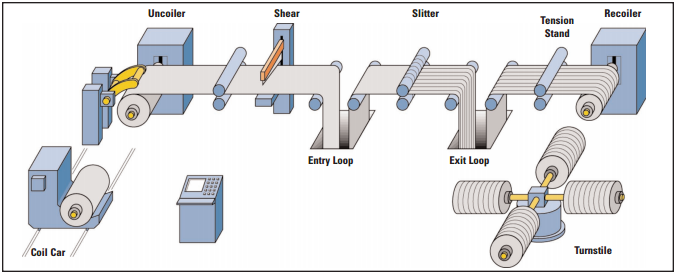

working flow of Metal Sheet Slitting Machine:

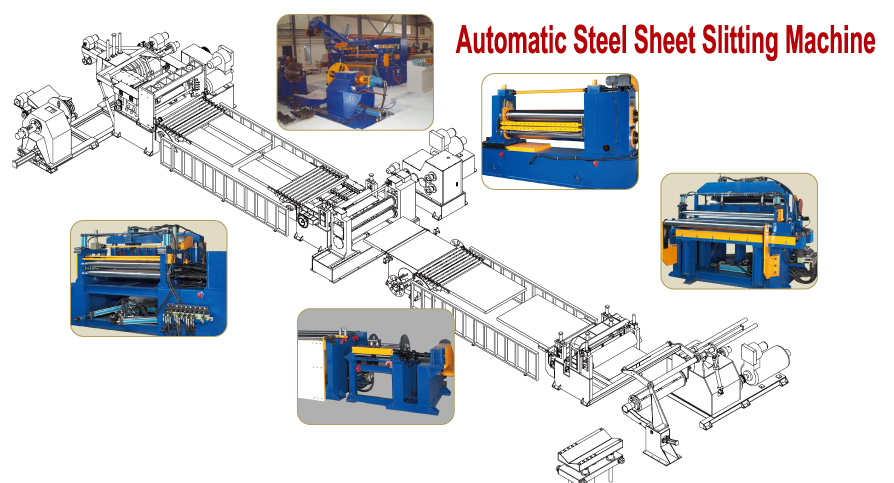

Here is the pictures of metal sheet slitting machine.

If you need detailed parameters of the machine, please tell me the specifications of the sheet you need to process, I will provide you with the data, to give you the technical solutions you need.

Such as:

1,coil .I.D (mm)

2,coil .O.D (mm)

3,MAX coil weight (Ton)

4,main material

5,max coil thickness (mm)

6,max coil width (mm)

7,voltage/ HZ

and so on :

Next:None